What is a Swamp Cooler?

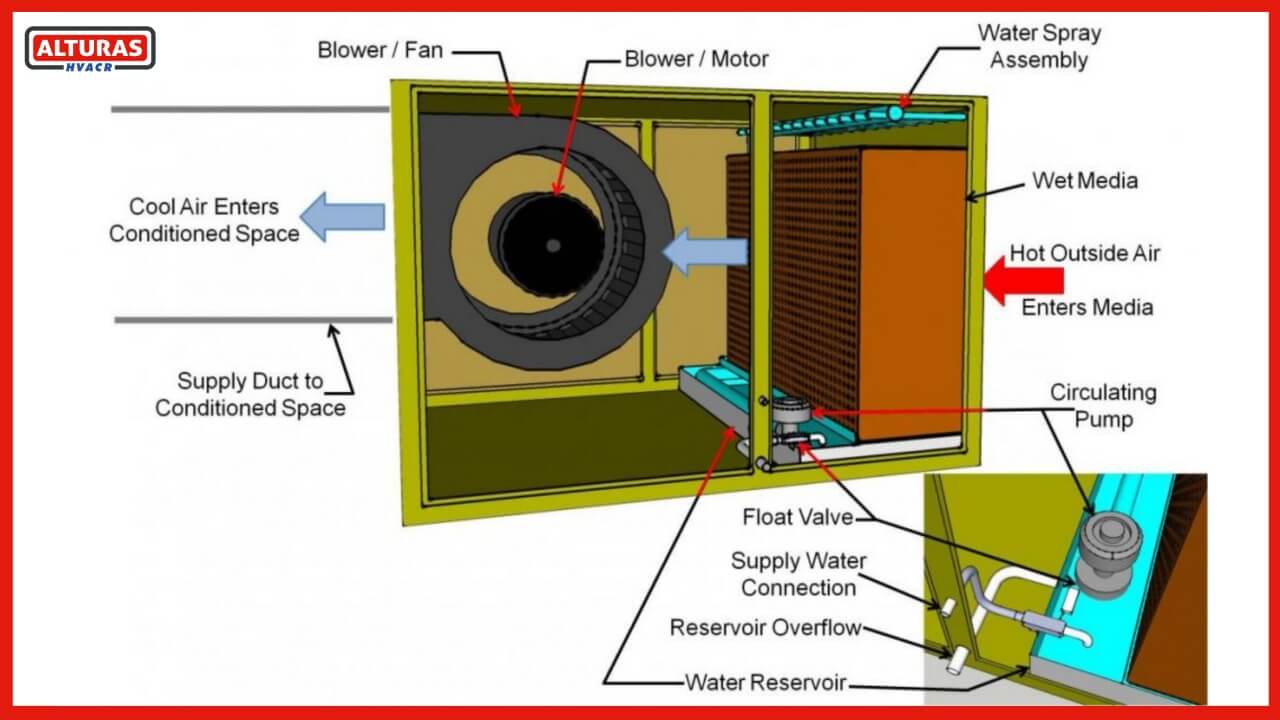

A swamp cooler, or evaporative cooler, cools air using the natural process of evaporation. They do not use refrigerant altogether, relying on a simpler process to bring down the temperature.

Why Swamp Coolers are Important?

Evaporative coolers are an essential component of Industrial and commercial areas. They cool air through the evaporation of water. Swamp coolers draw in dry, hot air using water and fans, then blow the air across a moistened pad.

As the water evaporates into the air, the air’s temperature lowers. In dry climates, it enhances air quality by adding moisture and functioning as a built-in humidifier.

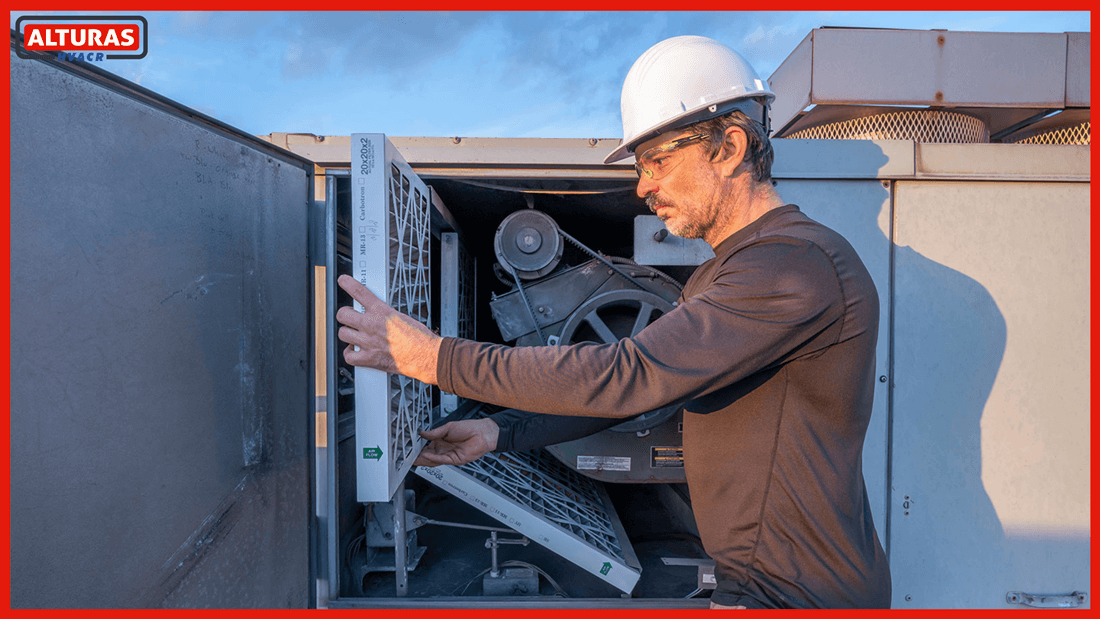

When your cooling system malfunctions, it’s good to call professional swamp cooler repair service providers. Alturas Contractors delivers reliable HVAC repair services to our customers with unwavering commitment.

Common Swamp Cooler Problems

Evaporative coolers are much simpler in function and more cost-effective than air conditioning systems. They can develop a range of problems over time that decrease their operating efficiency and performance. Following are some of the common problems of coolers that our technicians deal with day to day:

Mineral buildup

Mineral buildup is a common issue in hard water areas like Los Angeles. The more minerals the water contains, the faster mineral buildup will occur. Eventually, this buildup clogs the vents, and pads and blocks airflow. There are several ways to reduce mineral buildup:

- Zinc anode in the reservoir.

- Treatment tablets.

- A reservoir overflow.

- Water filter.

Mold formation

Mold buildup over time is another common problem with swamp coolers. Warmth and moisture create a breeding aid for mold and fungus. It accumulates when a belt-driven fan pushes the air through a cellulose pad that remains wet. The blower then distributes mold into the home.

Exposure to heat and sunlight significantly warms parts of the cooler, promoting mold formation. Maintaining evaporative coolers requires a thorough cleaning process to remove mold effectively.

Humid atmosphere

A persistent humid area can affect the cooler’s performance. Swamp coolers are much less effective in humid regions. The evaporative pads become saturated with water and debris builds up on them.

Faulty wiring

Another reason for coolers to break down is faulty wiring. This may cause persistent tripping of the circuit breaker, or blowing of fuses. If not treated timely, It’s also possible that the motor might cease operating. If this happens, it will be necessary to replace the wiring or the motor

Inadequate cooling

If your swamp cooler is not blowing cold air, there could be several problems causing the issue. You might have the thermostat set too high. A digital thermostat allows you to set the temperature. Then the cooler automatically runs until it reaches the desired temperature.

You must decide whether to set the fan to high or low. Adjusting the thermostat to a lower setting can resolve this issue.

There can be other reasons for inadequate cooling such as:

- Lack of adequate water saturation in the cooling pads.

- A malfunctioning pump.

- Clogs in the water recirculation system

The swamp cooler doesn’t turn on

There can be several reasons a swamp cooler doesn’t turn on.

- Check for a blown fuse

- Check for a tripped circuit breaker.

- Examine the wires connected to the fuse and breaker.

- Check for the thermostat. A faulty thermostat can affect the working of your motor.

- Check the belt that connects with the motor of the swamp cooler.

Musty odor coming from swamp cooler

A musty odor from your cooler often indicates stagnant water on the evaporative pads. Regularly check the pads and replace them as needed. Stagnant water in the sump can also produce an unpleasant smell. You should drain and clean it.

Insufficient airflow

Some of the reasons for insufficient airflow can be

- A loose or damaged belt on the ventilator motor.

- An issue with the fan belt or pulleys.

- Installation of the unit in a location where there is inadequate clearance for ventilation.

Request an Estimate